Automated Engine Assembly

Source: pixabay

Source: pixabay

- Short Engines

- Complete Engines

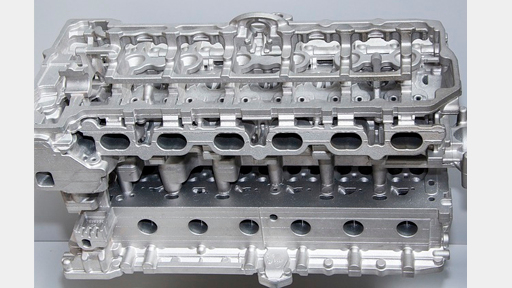

Assembly systems for short engines and complete engines are very large assembly machines with 80 to 130 stations and typical project volumes of up to 30 million euros. The customized assembly lines achieve cycle times of between 30 and 180 seconds during automated pre-assembly and final assembly. Assembly systems for fuselage engines have a high level of automation while assembly systems for complete engines have a higher manual proportion. The linkage with free circulation is realized with heavy longitudinal transfer accumulation roller conveyors for heavy loads up to 350 kg. In addition to joining by screws, force-displacement-monitored press-fitting and oiling are common. Also measuring and testing tasks such as presence and assembly control, axial clearance measurement, torque measurement, leak testing or electromechanical functional testing can be realized. Short engines and complete engines are fully assembled automotive combustion engines. The engine mounting system is the actual main assembly line. Typical operators are automotive OEM. Final assembly products are complete engines, which in addition to the fuselage engine additionally include all attachments and ancillaries such as intake system, fuel injection, oil pump and cooling system.

Products: Automated Engine Assembly

Suppliers: Automated Engine Assembly

| Anhua (Shanghai) automation engineering co. LTD., 200120 Shanghai, China | |

| ATS Automation Tooling Systems Inc, N3H 4R7 Cambridge, ON, Canada | |

| Aumann GmbH, 32339 Espelkamp, Germany | |

| Aumann Limbach-Oberfrohna GmbH, 9212 Limbach-Oberfrohna, Germany | |

| Gefit SpA Alessandria, Italy | |

| GROB-WERKE GmbH & Co. KG, 87719 Mindelheim, Germany | |

| KUKA Systems GmbH, 86165 Augsburg, Germany | |

| thyssenkrupp System Engineering GmbH Heilbronn, Germany | |

| VAF GmbH, 73441 Bopfingen, Germany |