ibg Prüfcomputer GmbH

Microstructure testing devices for top-hat rail mounting eddyguard S (digital)

- Single-channel structure testing devices for top-hat rail mounting in the control cabinet

- Preventive multi-frequency method (PMFP) with 8 test frequencies

- Continuous coil: up to 7 parts per second at 8 test frequencies

- Probe: up to 25 parts per second at 8 test frequencies

- iSHA - surface analysis

- Degree of protection IP 41, completely encapsulated housing

- Connections: IO ports for PLC connection (32 digital inputs and outputs), USB interface

- Dimensions: 239 x 165 x 169 mm

- Weight: 4 kg

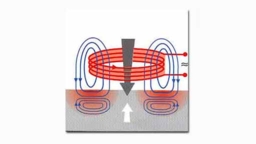

Eddyguard S (digital) microstructure testing devices from ibg are compact single-channel testing solutions for the detection of structural defects. Preventive multi-frequency testing can be used to detect even unexpected material defects. With the iSHA analysis, the test sensitivity is further increased by evaluating two top shafts of the eight test frequencies of the fundamental wave. The magnetic induction tests are started manually on a PC or laptop, via PLC control, with an optional start button or via an integrated autostart function. Operation, configuration as well as data storage and help functions can be realized with a PC or laptop connected to the USB interface. Test results are shown on the PC display as a bar chart or in relation to the tolerance fields. An extensive range of coils, tentative probes and continuous coils can be combined and used together. Unique features are the compact design for top-hat rail mounting in the control cabinet and the preventive multi-frequency test method.

Eddyguard S (digital) microstructure testing devices are single-channel solutions for simple structural tests with high production speed and high test sensitivity. Typical applications are the detection of heat treatment errors, the non-destructive testing of hardness and hardness depth as well as testing against material mix-ups. Typical test parts are bearing rollers, wheel flanges, toothed racks or deep-drawn parts. Users can be found in a variety of industries, with a focus on the automotive industry.