Kistler Straubenhardt GmbH (former Vester Elektronik GmbH)

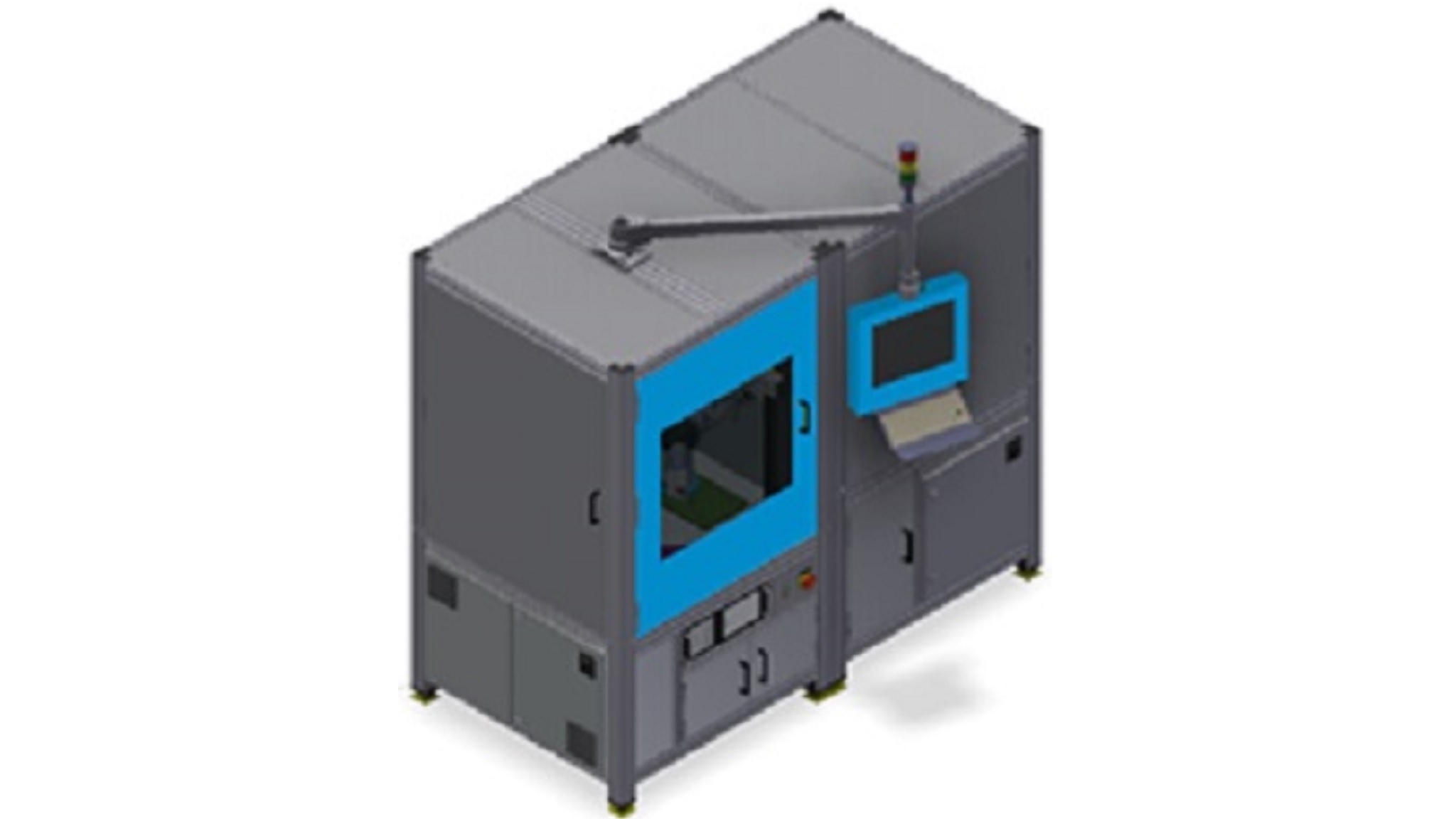

Testing station with glass turntable KVC 821

- Modular customer-specific testing and sorting machine for 100% inspection of small turned and pressed parts

- Test performance: up to approx. 500 parts / min, depending on part size and feeding system

- For clean small bulk material parts with stable component position

- Lighting: LED flash lighting, in transmitted and incident light, telecentric, coaxial and diffuse

- Triggering: Laser light barrier

- Cameras: CCD matrix cameras, b/w and colour

- Number of cameras: up to 8 CCD or CMOS cameras

- Measurement uncertainty: depending on the size of the image field and camera resolution, e.g. <0.005 mm

- Lenses: Bi-telecentric precision lenses (standard)

- Resolution: up to 16 million pixels (per camera)

- Integrated 24" TFT monitor for visualization

VIDEOcheck KVC 821 inspection and sorting machines from Kistler Straubenhardt GmbH (formerly Vester Elektronik GmbH) are universal inspection systems with digital camera measurement technology for 100% inspection of mass-produced parts. The measuring systems for small parts in bulk are available in two basic versions: KVC 821/C with integrated feeder and KVC 821/E with provided external feeder. Both versions can be extended in their basic conception with up to eight digital cameras of different resolution and four sorting and ejection stations to meet the increasing requirements in the field of surface testing and inspection. The "trevista®" reflected-light dome illumination based on "Shape from Shading" technology offers convincing solutions, especially in the field of surface inspection. Clean small parts with a stable lateral position can be inspected. The test specimens are conveyed by an internal or a provided feeder onto a transparent, permanently rotating glass ring, where they are inspected in up to four stations with up to eight image processing cameras. Test specimens can be recorded from above and below as well as from the side in transmitted or incident light, which enables partial measurement with high accuracy, checking the presence of internal threads as well as surface inspections. The inspection machine achieves inspection speeds of up to 500 parts/min and can achieve a measuring accuracy of < 5 µm. The modular design also allows the realization of complex tasks with high resolution at lower inspection speeds. Setup and operation are carried out via an integrated control unit with the aid of a Windows-based operating and parameterization software.