Micro-resistance Welding

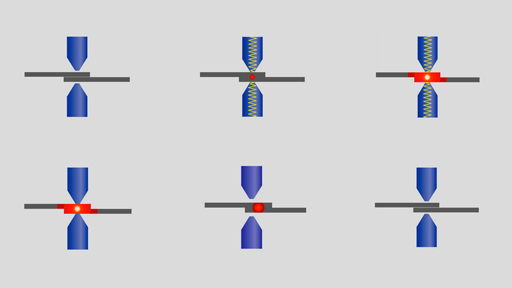

Welding machines, welding equipment and components for resistance welding are combined under resistance welding technology. In the case of resistance welding, the components to be connected are pressed together by welding guns or welding heads and are electrically melted at the contact point between the components by the welding current. Resistance welding is, according to DIN 1910, part of the process group of press joint welding, and is to be scientifically defined as conductive resistance pressure welding. In practice, the most important is spot welding or resistance spot welding, in which the point-shaped electrodes of the welding gun press the components to be connected directly together. In the case of projection welding the welding current in the component is guided in a targeted manner via absorptions, which are provided in the form of a construction or have previously been impressed in the sheet metal. Other methods are resistance butt welding and resistance roll seam welding. Necessary components of the resistance welding technology are the welding electrodes, welding guns or welding heads, a welding current source with welding transformer, the welding control and, if necessary, a process monitoring system.

Products: Micro-resistance Welding

Suppliers: Micro-resistance Welding

| Amada Miyachi Europe GmbH, 82178 Puchheim, Deutschland | |

| Credé Elektronik GmbH, 75181 Pforzheim, Deutschland | |

| Harms & Wende GmbH & Co. KG, 21079 Hamburg, Deutschland | |

| ima-tec GmbH, 97273 Kürnach, Deutschland | |

| Lingl Schweißtechnik GmbH, 82346 Andechs, Deutschland | |

| Matuschek Meßtechnik GmbH, 52477 Alsdorf, Deutschland |