Kistler Straubenhardt GmbH (former Vester Elektronik GmbH)

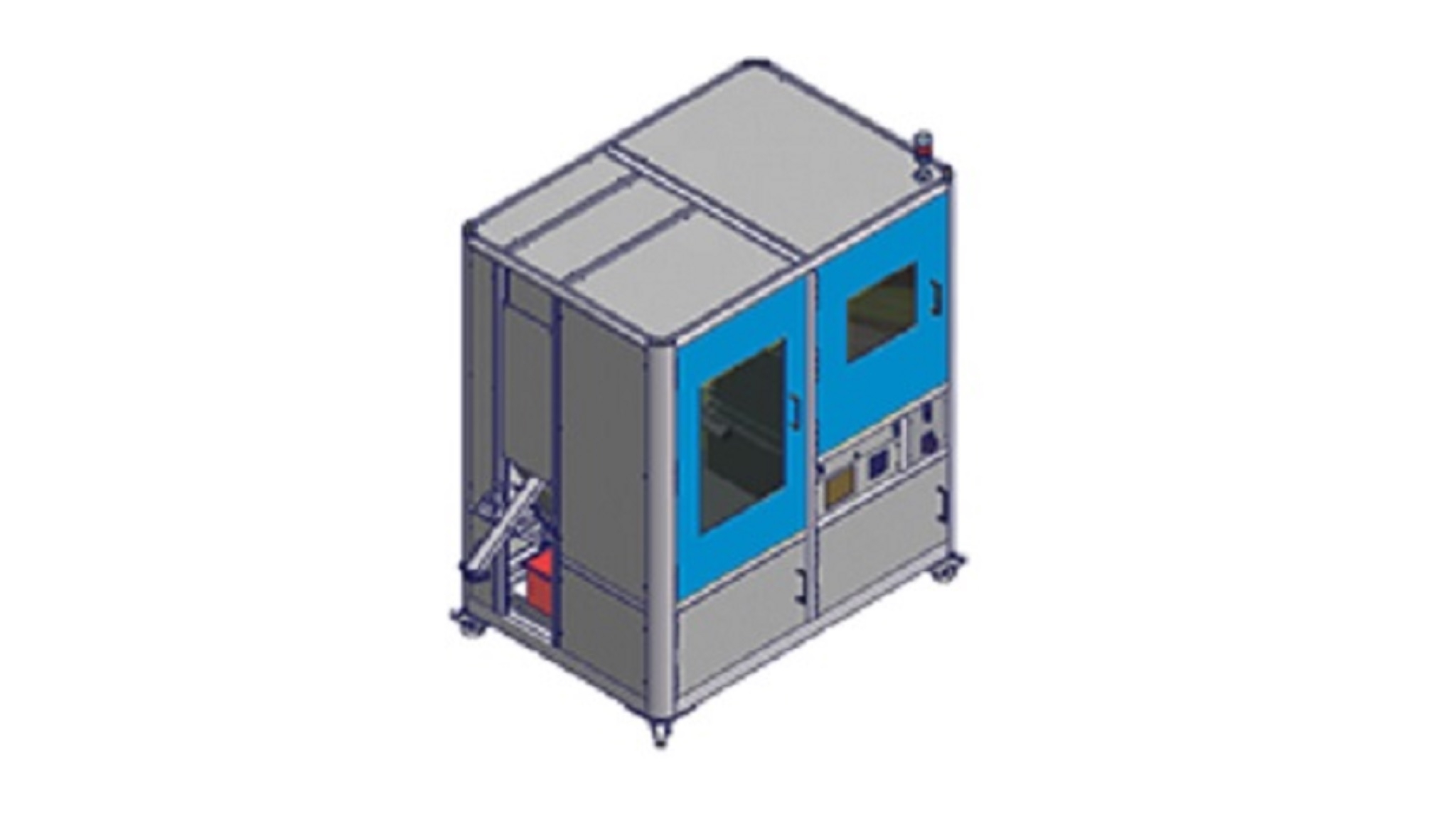

Measuring and Sorting Machine VIDEOcheck KVC 121

- Test performance: up to 250 parts/min

- Detection of internal chips in continuous bores possible

- Measurement accuracy (depending on camera resolution and image field size): up to <0.003 mm

- Prism or flatbed rail with adjustable side guide

- Up to 4 CCD cameras, Fire-Wire IEEE1394, b/w and/or color, resolution max. 2452 x 2054 pixels

- Telecentric precision lenses

- Windows-based image processing software with graphical user interface

- Vibratory bowl feeder with universal baffle

- Storage hopper with level control

- Separating device with chip separator

- Software for measured value documentation and statistical functions

- Hardness test can be integrated with ring coil

The automatic measuring and sorting machine VIDEOcheck KVC 121 is an absolutely measuring inspection system based on image processing for the 100% inspection of rotationally symmetrical and flat or disc-shaped small parts in bulk. Rotationally symmetrical turned parts with a length of 5-60 mm and a diameter of 1.5-10 mm can be inspected fully automatically for dimensional deviations of contour and external threads as well as for the presence of internal threads. For this purpose, the parts slide over a prism rail or hanging in a rail past the camera according to their stable position. Using a flatbed rail with adjustable lateral guidance, flat turned, pressed and punched parts with maximum dimensions of 60 mm x 60 mm are inspected. A stepped rail as well as a camera arranged in an axial direction can be used to detect e.g. internal chips in through holes. Optionally, the inspection machine can be equipped with up to four cameras. Depending on camera resolution and image field size, a measuring accuracy of <0.003 mm is possible and a maximum inspection speed of 250 parts/min. The inspection speed depends only on the feeding components, not on the image processing system. The image processing software with graphical user interface is used to define the relevant inspection criteria on the reference image. Interfaces offer the possibility of remote programming or connection to an existing CAQ system.