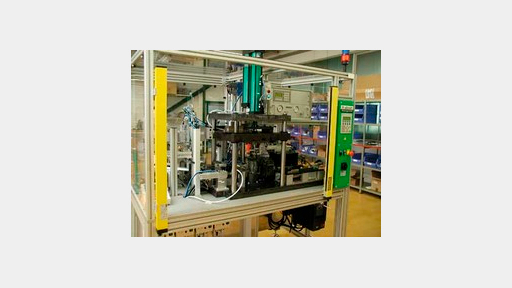

- Customized assembly, leak testing and functional testing systems

- Processes: joining, checking, adjusting, marking, etc.

- Component variants can be flexibly adopted using changing devices

- Automatic good / bad sorting

- Control via industrial PC or PLC

- Optional: simple mechanical, electrical and optical tests

Customer-specific assembly, leak testing and functional testing systems by Dr. Wiesner Steuerungstechnik GmbH are fully automatic concatenated complete solutions. They are used to test fluidic products that require complex leak and function tests. Typical products are hydraulic and pneumatic valves as well as turbochargers. In addition, for profitability reasons, the integration of precedent assembly or pre-assembly processes can be reasonable. Turnkey solutions adopt assembly and testing processes and also adjustment and adjustment tasks as well as labeling and packaging processes. A good / bad sorting of the components takes place after testing is done, as well. Capable linking system, feeding and handling systems, task-specific process stations and so on offer a wide range of varieties. Besides the integrated control function of the testing device or higher-level PLC, numerous interfaces are available for a higher-level master computer connection.

Users can be found in the automotive and automotive supply industry and in other industries.