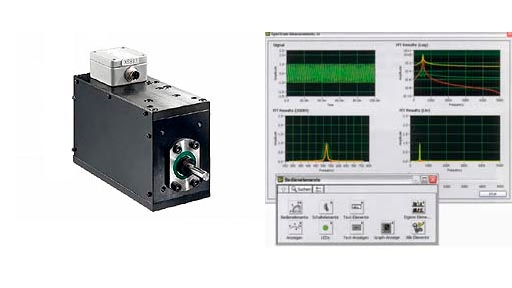

Test Modules for Torque-Angle Monitoring

- Typical tasks are the automated 100% inspection, the friction torque measurements on adjustment elements and ball bearings, the inspection of dampers, springs and spring step systems as well as, for example, the inspection of the holding and withdrawal forces of magnet systems

Mechanical test modules for torque/rotation-angle progression or monitoring are test bench and test equipment components for 100% mechanical inspection. They are used for mechanical functional testing of finished products and assemblies. Test modules are based on controlled drives introducing defined torques and angles of rotation into the test object and are equipped with sensors for measuring variables. For functional testing, the test item is subjected to mechanical input variables by the test module in order to simulate certain operating conditions and to compare the resulting output variables with a nominal value. The product to be tested responds to the input variables with rotary and linear movements. These are detected by sensors, conditioned, digitized and transferred to the measurement data evaluation. This calculates the characteristic values to be tested from the measuring signals and compares them with the nominal values of faultless products. In principle, not every single component is tested for function during the functional test, but it is assumed that all individual functions are also correct if the overall result is correct. Typical tasks include automated 100% control, testing of electrical switching elements, mechanical latching and locking components, testing of dampers, springs and spring-tread systems and controls of holding and withdrawal forces of magnetic systems. Typical products are mechanical products such as combustion engines and transmissions, electrical products such as electric motors and household appliances, electronic products such as automotive control devices and mobile phones or fluidic components such as pumps and valves. For a functioning test system, a workpiece holder for fixing the test object as well as a sequence control, an optional measurement data acquisition and evaluation as well as the user interface are required. User branches are internal equipment construction, test systems as well as the special machine and system engineering for the automotive and automobile supply industry, manufacturers of electrical components, electrical and domestic appliances and other industries.

Suppliers: Test Modules for Torque-Angle Monitoring

| Promess Gesellschaft für Montage- und Prüfsysteme mbH, Berlin, Germany |