Sound Analysis for Material Testing

- Acoustic resonance analysis for 100% control of function- and safety-critical components in the production line as well as in manual test benches

- Fields of application: Testing of steel, cast components made of nodular cast iron, grey cast iron, sintered metal and aluminium or products made of ceramics and glass

- Typical test specimens: automotive components such as connecting rods, brake discs and gear wheels or roof tiles and glass

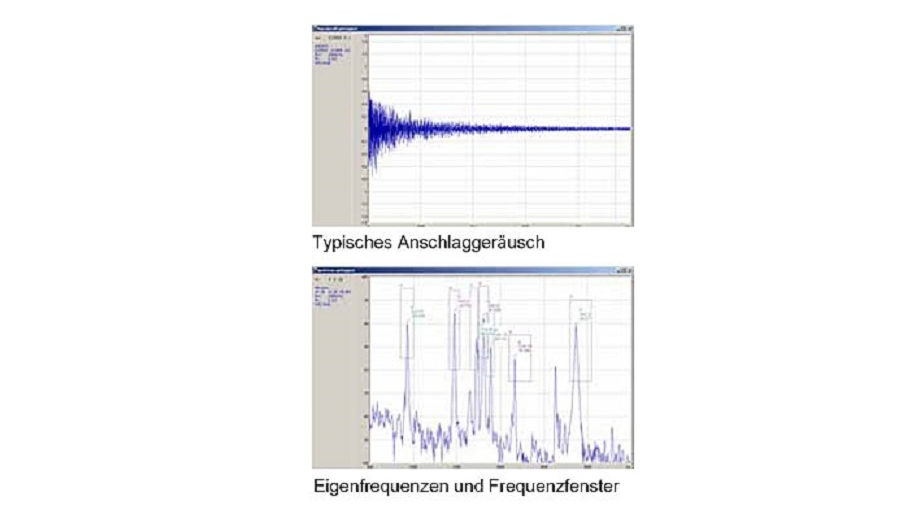

The so-called sound analysis, also known as acoustic resonance analysis or vibroacoustic resonance testing, is a method of non-destructive material testing for detecting cracks as well as material and structural defects. The frequency spectrum includes both acoustic frequencies and the ultrasonic range. Rigid bodies exhibit a characteristic natural oscillation when excited, e.g. by impact or sound waves, which is changed by material defects. The test specimen is fixed, struck in a defined manner and the resulting natural vibrations are recorded. The vibration behaviour is then compared with the previously taught-in vibration behaviour of defect-free components as a nominal value and evaluated. A test device typically comprises a workpiece fixture, a device for striking, application-specific selected sound transducers as well as a control and evaluation unit with corresponding software.

To set up a test application, the characteristic vibration behaviour of a component is determined by measuring a series of defect-free test specimens as a nominal value and the permissible tolerances are defined.

The test specimen is excited in a defined manner, e.g. by striking or piezoelectric sound emitters. The vibration behaviour of the resonance frequencies is recorded with application-specific sound transducers such as microphones or solid-borne sound transducers. The signals are digitally evaluated and compared with the pre-programmed target values. The evaluation can determine, for example, the shift of individual or all resonance frequencies or the absence of individual lines as well as a spreading, distance change, level attenuation or modulation of the frequencies. Defects such as cracks, structural changes, structural loosening or dimensional deviations can be detected.

Suppliers: Sound Analysis for Material Testing

| MAUL-THEET SYSTEME GmbH, Berlin, Germany |

| RTE Akustik + Prüftechnik GmbH, Pfinztal/ Karlsruhe, Germany |