Automated Safety Critical Screwing

Source: AMT

Source: AMT

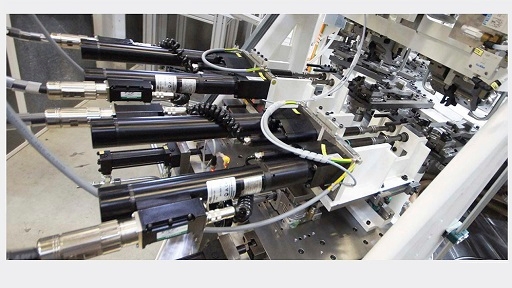

Fixture transducer control tools are screw units for installation in automatic screwing station, in which the screws are provided in the screwed position of the workpiece. The screw feed is performed manually or by a separate automatic device. The stationary use of transducer control tools requires an automatic screwdriver stroke in order to follow the screw head during screwing in. For cost-saving adaptation to the respective screw application, fixture nutrunners are mostly modular and typically comprise different drive modules with and without deflection, graduated gearing, measuring modules for torque and angle of rotation with adapted measuring ranges. Stationary screw spindles are driven into the actual screw position by a machine-side feed slide. In the case of stationary use of screw spindles, the feed movement of the screwing tool must also be automated in order to follow the screw head during screwing in. This is usually done by means of a resilient screw-tool holder, which is pretensioned by the feed carriage. We use stationary screw spindles in semi-automatic and fully automatic screw systems for medium and heavy products. Typically, screws from size M6 are fed into the screwed position and then screwed with screwed spindles. Typical products are automotive assemblies such as engine assemblies, gearboxes, axles or articulated shafts. Main industries are the automotive and automotive supply industries. Corded transducer control tools are used for the monitored manual torque and angle controlled screw mounting and are equipped with standard software for all common screwdriving applications. The system fulfills the requirements for functional and safety-critical fittings with documentation requirements. A typical application is the assembly of car components or the final vehicle assembly. The most important users are the automotive supply and automotive industry. Application of Cordless transducer control tools is the manual torque- and angle-controlled screw mounting. The cordless hand-held tools enable the production of functional and safety-critical screw connections with documentation requirements, if cable-connected screwdrivers can not be used or offer the necessary flexibility. A typical area of application is the final assembly of the vehicle on the assembly line. The main application sector is the automotive industry. Standard torque control methods include the following: Torque control, angle-of-rotation control and stretch control: After the screw head is installed, the screw is tightened to the desired torque The screw head is within the specified tolerance. Torque control is only used in simple screwdriving situations since no precisely defined biasing force can be applied due to the high friction coefficient fluctuations. If the coefficient of friction is too low, the plugging limit can be exceeded. If the friction coefficient is too high, the minimum pretensioning force is not reached. Conversely, in the case of the angle of rotation control, the screw is tightened further by a predetermined angle after the head has been placed, and the tolerancing of the adjusting torque is subsequently monitored. With a rotation angle control, over-elastic tightening beyond the stretching limit is also possible. In any case, a much more precise adjustment of the pre-mounting force than in the case of the rotation angle control is possible.

Products: Automated Safety Critical Screwing

Suppliers: Automated Safety Critical Screwing

| Atlas Copco AB Tools and Assembly Systems, 105 23 Stockholm, Schweden | |

| Bosch Rexroth AG - Electric Drives and Controls - Schraub- und Einpresssysteme, 71534 Murrhardt, Deutschland | |

| DEPRAG SCHULZ GmbH u. CO, 92224 Amberg, Deutschland | |

| Desoutter GmbH, 63477 Maintal, Deutschland | |

| Dixon Automatic Tool, Inc., IL 61104 Rockford, USA | |

| ems-automation gmbh, 37589 Westerhof, Deutschland | |

| EST Elektronische Schraub- + Steuerungstechnologie GmbH & Co. KG, 73432 Aalen-Ebnat, Deutschland | |

| Stanley Engineered Fastening Assembly Technologies, OH 44143 Cleveland, USA | |

| WSM Automation GmbH, 44577 Castrop-Rauxel, Deutschland |