Wobble Riveting

- Window and Door Fittings

- Furniture Fittings

- Car Fittings

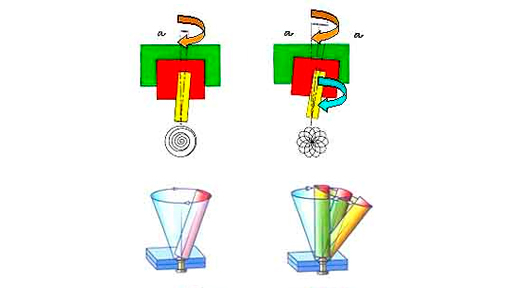

Wobble Riveting and Radial Riveting, the latter also known as Radial Point Riveting or 3D Wobble Riveting, are direct riveting processes for producing high-quality riveted joints. The forming process is carried out by web-shaped point forming of the closing head with a riveting punch that is inclined at an angle to the axis of the rivet. The riveting punch circles the closing head with a predefined movement over the entire circumference, which is combined with an axial feed movement. As a result, the yield point of the material is exceeded at certain points, so that the rivet material begins to flow and is cold-formed. The punctiform rolling of the riveting punch causes not only a deformation of the rivet in line with the material, but also a gentle treatment of the rivet surface, which remains largely intact. In wobble riveting, the rivet head describes a wobbling movement on a circular path. In radial riveting, the movement of the riveting punch follows a rosette path.

The processes of Wobble and Radial Riveting are based together on the principle of continuously cold forming the closing head in a point-like manner by reaching the yield point, but they differ in the movement pattern of the riveting punch. Despite high forming performance, the tools experience a low specific load and the sliding friction between the riveting punch and the workpiece is minimised. In addition, the forming process can be controlled by force-displacement monitoring. In Wobble Riveting, the riveting punch is permanently rotated around the closing head, whereby the punch is inclined at a constant angle to the axis of the rivet. In addition, there is an axial feed movement through the riveting press. The point of impact of the riveting punch follows a downward inclined spiral, causing the material to flow primarily in an axial and tangential direction. In the Radial Riveting process, the riveting punch describes a rosette path, a so-called hypocycloid. The movement on a rosette path is created by two superimposed wobbling movements of the riveting punch. The rivet material is gently formed without any noticeable structural change. The material flow is primarily in axial and radial direction.

Suppliers: Wobble Riveting

| Aguirregomezcorta Y Mendicute S. A., Eibar (Guipuzcoa), Spanien | |

| Bodmer Küsnacht AG, Küsnacht, Schweiz | |

| D. Friedrich GmbH & Co. KG, Remshalden, Deutschland | |

| Ingenieurbüro Ing. grad. Uwe Tank GmbH, Walsrode, Deutschland | |

| KMT Produktions- + Montage-Technik GmbH, VS-Schwenningen, Deutschland | |

| KMT-Vogt Niet- und Fördertechnik e.K., Villingen-Schwenningen, Deutschland | |

| S. DUNKES GmbH, Kirchheim / Teck, Deutschland |