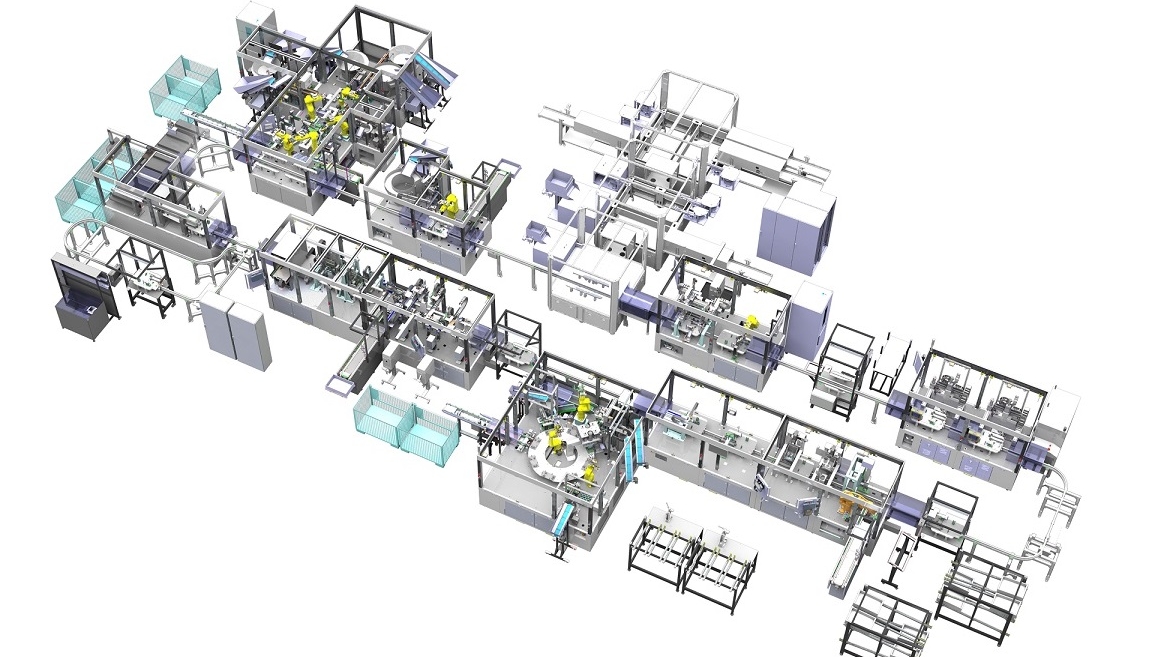

- 70 assembly processes / 30 inspection processes

- Goods carrier transport system with 40 goods carrier shuttles incl. RFID

- 17 different process modules integrated in the assembly line

- 4 integrated manual workstations

- 11x industrial robots incl. gripper systems

- 12x vibratory bowl feeders with hopper systems and parts separators

- 4x MAi tray stacker

- 2x 3D camera system

- 10x industrial camera systems in the line

- 2x hot riveting stations

- 3x fully automatic screwing stations

- 3x automatic greasing stations

- 2x automatic dosing stations for adhesive application

- 2x EOL test stations

- Labelling and reading station

- Cycle time 15 sec./module

Assembly lines for actuators are customer-specific assembly and test lines for the production of a wide variety of actuators and drives.

The modular process modules can include a wide variety of assembly and testing processes and, depending on the requirements, are linked with various goods carrier transport systems to form turnkey assembly and testing lines. In addition to fully automatic lines, semi-automatic lines with integrated manual workstations can also be realised. Project or customer-specific requirements for the feeding of unfinished parts as well as for the packaging of finished parts can be implemented by integrating e.g. spiral conveyors, step conveyors, flex feeders as well as MAi tray stackers. Process data acquisition/traceability can also be mapped in M.A.i's innovative automation. In total, more than 100 different assembly, joining, machining and testing processes can be integrated in one line.