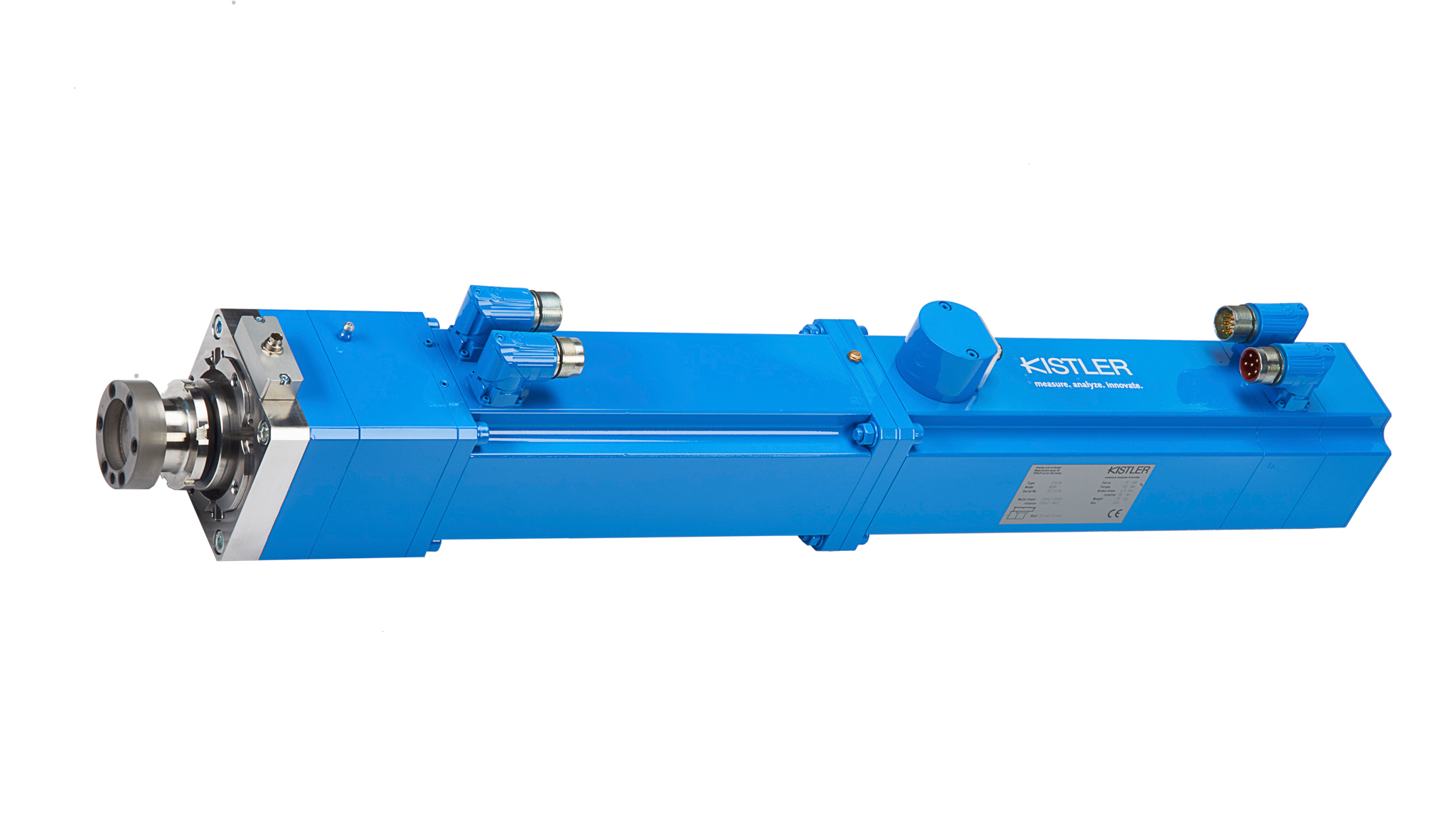

- Measuring direction: Pressure / tension monitoring system maXYmos NC

- Measuring range of 5 and 15 kN

- Travel speeds: up to 400 mm / s

- Stroke: 400 mm

The electromechanical joining systems NCFR are suitable for linear joining processes with simultaneous or sequential rotation of the plunger. Separate linear and rotary motion sequences can be implemented via sequencing elements. NCFR modules can represent complex joining processes and are equipped with integrated force sensors and powerful force-path evaluation for gapless process monitoring and documentation. In addition to the force-travel evaluation, torque can be measured and evaluated simultaneously via angle or time using the optional torque sensor. Various interfaces are available for the control. PROFIBUS, PROFINET, EtherNet / IP or EtherCAT can be used. Data can be transmitted, visualized and archived via various interfaces.

NCFR joining modules are used for press-in operations with high requirements such as measuring the torque of rotation during press-fitting, cycle time and combined handling tasks, available in one size only. NCFRs consist of a robust housing with 2 hollow shaft motors, integrated piezoelectric force sensor, absolute value transmitter and holding brakes. The joining module is operated with the servo amplifiers IndraDrive and the monitoring system maXYmos NC, which, in addition to force and displacement, also evaluates and documents torque over rotation angles at the same time. Support rail adapters, display modules and connection cables are optional. The lightweight joining modules with compact design are typically used in the automotive and automotive supply industry.