InfraTec GmbH Infrarotsensorik und Messtechnik

Thermography solutions for rotary test benches

- Thermography solution for integration in rotary test benches

- Thermal imaging camera ImageIR ® 5300 series or 8300 hp series

- Spectral range: (2.0 ... 5.0) µm

- Maximum resolution: (320 x 256) IR pixels or (640 x 512) IR pixel

- IR frame rate: up to 13 kHz (partial image)

- Thermal sensitivity up to 0.015 K

- Integration time: (0.1 ... 20,000) µs or (10 ... 200) µs

- Measurement accuracy : +/- 1%

- Radiator: High-performance Stirling radiator

- Remote control via various interfaces

- Motorized, remote-controlled filter wheel with up to 5 filter positions (optional)

- Motorized, remote-controlled aperture wheel with up to 5 aperture positions (optional)

- Trigger interface: TTL I / O (optional)

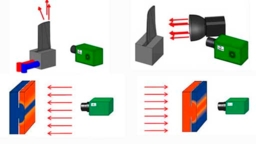

Thermography solutions for rotary test benches TRC - Thermal Rotate Control are used for load tests when testing rotating parts such as brake discs, tires and clutches for temperature profile measurement using passive thermography. The measurement object is measured with a sampling rate of several kilohertz.

For tests on rotating parts, high requirements with regard to thermal resolution and repetition rates have to be met in order to record the thermal development with increasing load in detail. The thermography cameras of the solution meet these requirements with a high thermal resolution and a high data transmission rate and instantaneous triggerability.

The thermography solution includes the measurement variants of a real-time profile measurement and a segment measurement. With these functions, the temperature of the rotating part can be mapped and analyzed both point in time and period. The IRBIS ® 3 rotate thermography software is used to analyze the observation data. This includes automatic hotspot detection, an alarm function when certain temperature limit values are reached in the live stress test, measurement in various transformation views, a synchronous recording of the raw data and an online display in the test sequence. The software IRBIS ® 3 professional can also be used for analysis of measurement, which include the functions of exporting video, image and measured values, 3D visualization, a report generator (based on Microsoft Word) and a difference image analysis.

For camera control and data acquisition, the camera is coupled to the high-performance computer via the GigE interface. The temperature data is automatically triggered by the system.

A special function of the thermography solution for rotary test benches TRC - Thermal Rotate Control is the simultaneous acquisition of all pixels of an image or a line by using a snapshot detector. This means that thermal data can be recorded for the smallest periods in the microsecond range.

The test parts include rotating parts in brakes, undercarriages and clutches such as brake discs, sintered metal parts, rims, shafts and ball bearings. Customers of the InfraTec thermography solution come from the automotive industry, the automotive supply sector and rail vehicle construction.