- Automated thermography solution (stand-alone or system integration in existing systems)

- Thermal imaging camera ImageIR ® 5300, 8300 hp or 9300 series, the VarioCAM ® hr head 600 series or the VarioCAM ® HD head 600 or 800 -Series

- Spectral range: (2.0 - 5.5) µm

- Maximum resolution: (320 x 256) IR pixels, (640 x 512) IR pixels, (1,024 x 768) IR pixels or (1,280 x 1,024 ) IR pixels

- IR frame rate: from 60 Hz to 13 kHz

- Thermal sensitivity up to 0.015 K

- Integration time: (1 ... 20,000) µs or (0.6 ... 20,000) µs (ImageIR ® Series)

- Measuring accuracy: +/- 1% (ImageIR ® series)

- Radiator: high-performance Stirling cooler (ImageIR ® series)

- Motorized, remote-controlled filter wheel with up to 5 filter positions (optional ImageIR ® series)

- Motorized, remote-controlled aperture wheel with up to 5 aperture positions (optional ImageIR ® series)

- Trigger interface : TTL I / O (ImageIR ® series)

- (Random) subwindowing (integrated with ImageIR ® 5300, 8300 and 9300 series)

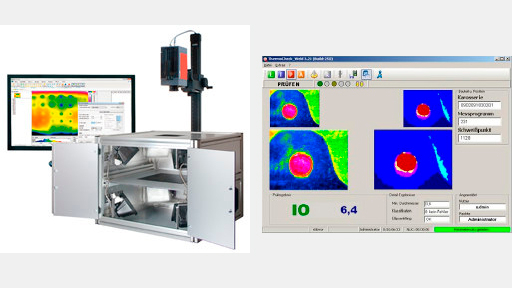

Full automatic test stations of InfraTec for heat flow thermography are used for non-destructive quality inspection of connections such as resistance and laser welding connections or adhesive layers (in components). Sources of error such as cracks, binding errors and missing connections in laser weld seams, cavities in plastic parts or delaminations and inserts in composite materials are identified. The test is carried out using active thermography, which provides indications of possible errors and the quality of the connections by briefly heating the surface of the connections and recognizing the temperature profile.

Infrared cameras of the ImageIR ® series are primarily used for this application.

The modular design enables application-specific configuration of the camera as well as subsequent adaptation to changing requirements. Different emission and transmission properties of materials can be taken into account as part of special measurements with the help of spectral filters.

The thermography camera is connected to an external control and evaluation unit in the control cabinet with the IRBIS ® 3 active thermography software for displaying and analyzing the data obtained. The software provides the user with feedback on the test results by displaying an infrared test image. The data is stored on the control and evaluation unit. Excitation and data acquisition synchronization take place via special control units developed by InfraTec. The solution is used by manufacturers of components and subassemblies made of fiber composite materials, whose elements are joined together by layered compounds. This includes all manufacturers of automobiles, airplanes and other means of transportation as well as manufacturers from the respective supply areas.