EMG Engineering & Maschinenbau Gesellschaft mbH

Joining modules FGM with external NC control

- available in eight sizes with different product variants

- maximum forces of 0.5 up to 300 kN with a robust ball screw or for press forces from 160 kN with roller thread spindle in both the compression and tension directions

- maximum traversing speeds range from 100 mm/s to 240 mm/s

- stroke lengths between 0-100 and 0-700 mm, standard stroke 250 mm

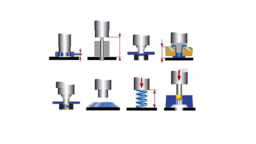

The joining modules FGM with external NC control are electromechanical pressing, pulling and joining systems, available in eight sizes with different product variants. FGM modules offer maximum forces of 0.5 up to 300 kN with a robust ball screw or for press forces from 160 kN with roller thread spindle in both the compression and tension directions. The maximum traversing speeds range from 100 mm/s to 240 mm/s. Depending on the product variant, the stroke lengths are between 0-100 and 0-700 mm, the standard stroke is 250 mm. The press modules can be installed either standing or horizontal. The force of the spindle is measured with a piezoelectric force transducer integrated in the tool holder. The actual forces on the tool are thus determined without the friction of the spindle or the pressure tube distorting the measurement. This allows a force control with an accuracy of <1% of the nominal value and a high reproducibility of the process. Resolvers with a resolution of 0.005 mm are integrated in the drive for displacement measurement. Optionally, the press path can be monitored and controlled via a separate displacement sensor on the tool, which allows a repeat accuracy of up to 0.01 mm. For the press modules a modular, expandable NC control system is available with which up to four joining modules with force-distance monitoring via envelope curves can be evaluated. Programming, evaluation and documentation are carried out via a user-friendly user interface on the PC. The controller provides digital inputs and outputs as well as CanBus, ProfiBus, InterBus-S and Ethernet interfaces with which an external PLC can be connected as well.

The electric joining module is integrated into a solid housing and consists of the ball screw, tool holder with force transducer as well as the drive with servo motor, resolver and toothed timing belt for power transmission. For press forces starting at 160 kN, roller winding spindles are used. Optionally a control unit for up to four servo-presses as well as software for programming, evaluation and documentation is available. Furthermore, the press path can be monitored with a separate drive on the tool, if needed.