- semi-automatic single workstations with manual or fully automated feeding, pressing or joining

- with maximum press forces of 1-20, 40-120 or 160-250 kN

- maximum traversing speeds of 100 mm/s up to 240 mm/s

- Upstrokes between 0-100 and 0-350 mm are possible, the standard stroke is 250 mm

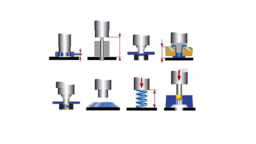

EMG assembly and press-in stations are semi-automatic single workstations with manual or fully automated feeding, pressing or joining. The stations are based on the electric FGM servo press modules and are available in three sizes with maximum press forces of 1-20, 40-120 or 160-250 kN. The robust spindle press modules achieve maximum traversing speeds of 100 mm/s up to 240 mm/s. Upstrokes between 0-100 and 0-350 mm are possible, the standard stroke is 250 mm. EMG assembly and press-in stations can be customized or adapted to customer specifications. This can include automatic feeding and removal devices right up to robot handling or chaining and handling devices, workpiece holders or press-fit tools. A piezoelectric force transducer integrated in the tool holder allows a force control with an accuracy of <1% of the nominal value and a high reproducibility of the process. The distance measurement is integrated into the drive or the press path is monitored and controlled via a separate displacement transducer at the tool holder, which allows a repeat accuracy of up to 0.01 mm. The process parameters such as traversing distance, force, speed or braking and acceleration ramps are controlled and monitored by the control system. Programming, evaluation and documentation are carried out via the integrated operating unit or via a graphical user interface on the PC.

The stations consist of three basic models in different sizes, which are graded according to the maximum pressing force. The station comprises a solid base, a protective enclosure, an electric press-fit module of the FGM series with force-distance monitoring on a stand construction as well as the control and operating unit. The basic model can be extended by the user or delivered as customer-specific turnkey assembly and press-in stations. This can include automatic feeding and removal devices right up to robotic handling, linking and handling devices or workpiece fixtures right up to the press-in tools.