Piston rods must be inspected for cracks after the final surface treatment. Cracks must be detected regardless of their orientation, whether transverse or longitudinal to the rod, from a depth of 50 µm, a width of 75 µm and a length of 5 mm. The inspection must be integrated into the production chain.

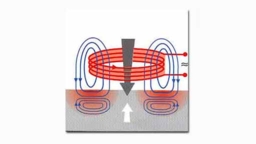

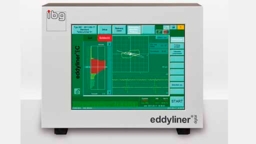

The task was carried out using the eddydector crack detector in the 2-channel version and the eddyscan H rotating head. The piston rods are gently guided through the rotating head by synchronously running trapezoidal rollers. The rotating head is equipped with an interchangeable probe disc. By changing the disc, the rotating head can be quickly converted to a new part diameter. Edge suppression is controlled by adjustable fork light barriers. Two probes located in the disc rotate around the piston rod without contact. The conveyor movement ensures that the surface is scanned without gaps. An automatic ejector removes non-conforming parts immediately after inspection. Up to 20 parts/min with a part diameter of 8-30 mm can be inspected.

Translated with DeepL.com (free version)

The performance data achieved and the automatic test sequence enable integration into the production cycle. This has made it possible to implement reliable 100% testing in a cost-effective manner.