- Electrical screw solutions for torque- and angle-controlled screw connections in automated production

- Primary controller is available in versions with Profibus, DeviceNet, Ethernet IP and ModBus TCP

- Secondary controller is sold with and without an Ethernet switch only

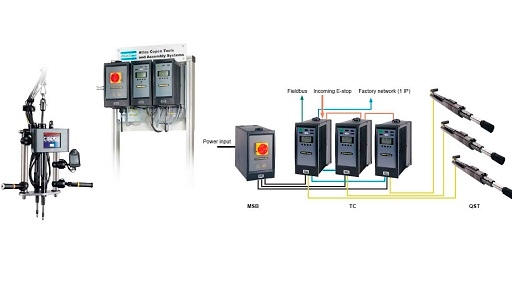

With the PowerMACS 4000 installation screw system, Atlas Copco offers electrical screw solutions for torque- and angle-controlled screw connections in automated production. The QST screw spindles are equipped with torque and angle-angle encoders for screw-process monitoring. Some screw spindles are equipped with several torque and rotary angle sensors. The torque range from 2 to 8000 Nm is covered with an accuracy of +/- 2.5% over 6 sigma. The system consists of primary and secondary control units, a main switch box (MSB), possibly the distribution box (DB) and QST stationary screw spindles. PowerMACS 4000 offers a wide range of bolting strategies, a fast-response automatic shut-off, reject management for the efficient elimination of faulty screw connections, as well as comprehensive statistics and backup functions. The digital system is network-compatible and enables an exact synchronization without the need for an additional PC. The programming is carried out via the PC software ToolsTalk PowerMACS World Release 10, the networking via the computer tools Tools Net. Fieldbuses, an Ethernet switch and four I/O are available for communication. Optional modules are a mini-display, signal column, indicator box, status PC for operating software, I/O extension and operator panel.

The number of system components depends on the number of screw spindles. In the case of multi-spindle solutions, a secondary control (TC-S) is required for each additional spindle in addition to a PowerMACS primary control (TC-P). In addition to a main switch box (MSB), at least one distribution box (DB) is required from seven spindles. TC-S and TC-P differ in the available interfaces.